Specifications

- Type:

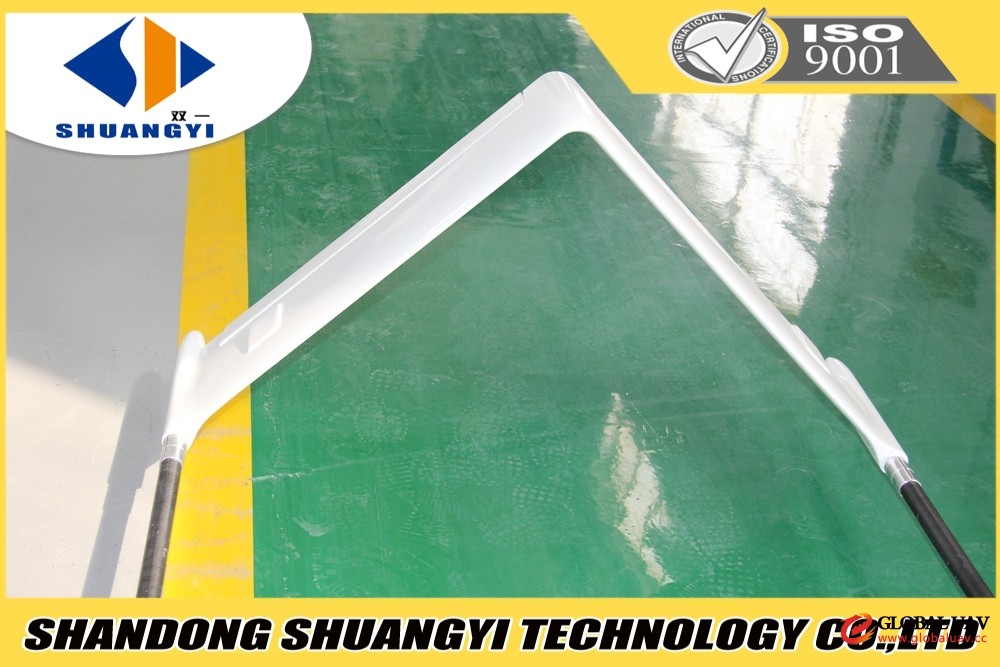

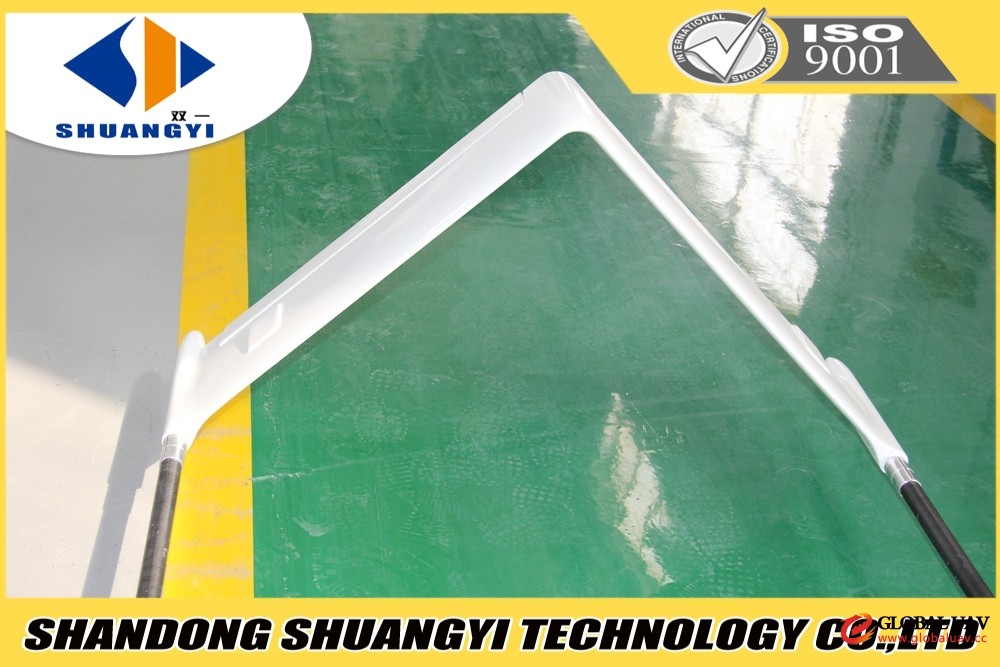

- FRP, Unmanned Aerial Vehicle

- Condition:

- New

- Year Built:

- 2014

- Place of Origin:

- Shandong, China (Mainland)

- Model Number:

- 001

- product name:

- electric UAV professional drones

- condition:

- NEW

- Power source:

- Gasoline Engine

- Weight:

- 15KG

- Flying Height:

- 4000M

- Cruising Time:

- 8-10HOURS

- Cruising Speed:

- 110km/h

- Recovery Model:

- downhill race

- Material:

- FRP

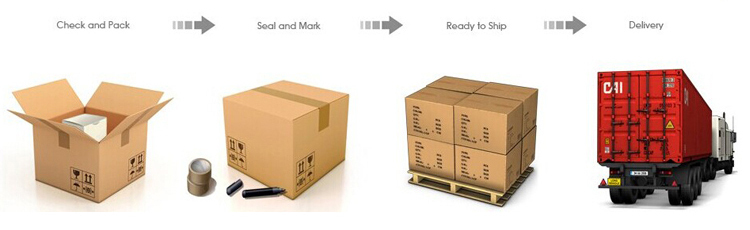

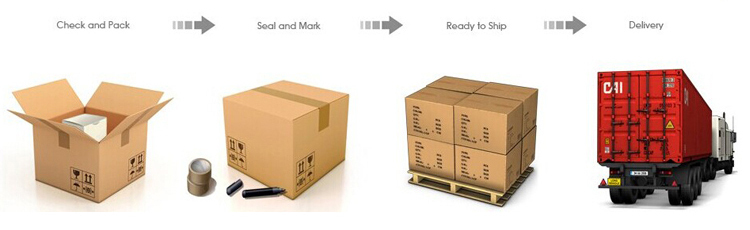

- Packaging Details:

- Canvas, bubble paper standard package, or as required.

- Delivery Detail:

- 8-10 weeks after deposit received

| ItemName | electric UAV professional drones | |||||||||

| Material | Carbonglassfiber,resin,gelcoat | |||||||||

| Size | ||||||||||

| Color | Red/Black/asrequired | |||||||||

| Process | Carbonglassfiber,resin,gelcoat | |||||||||

| CustomDesigh | Welcome | |||||||||

| Service | OEM&ODM | |||||||||

| MOQ | 1set | |||||||||

| Sample | NO | |||||||||

|

SampleCost,Thecostwillbe returnedafterplacinganorder |

||||||||||

| SampleLeadTime | ||||||||||

| PaymentTerms | T/T;L/C | |||||||||

| Packing |

Canvas,bubblepaperstandardpackage, orasrequired. |

|||||||||

| ProductionTime | 8-10weeksafterdepositreceived | |||||||||

| DeliveryPort | Qingdao | |||||||||

![]()

1,Wind turbine Plug and Mould :wind turbine blade plug;yacht plug;composite plug for high-speed railvehicle and light rail vehicle; wind turbine blade mould;main mould;spar cap mould;yacht mould ;water heating mould ;electric heating mould;

2,Nacelle cover 1.5MW nacelle cover 2.0MW nacelle cover 3.0MW nacelle cover 5.0MW nacelle cover, 7.0MW nacelle cover

3,Process:VARI process mould ; Engineering machinery DCPD hood;Hand lay-up process;Vacuum bagging process

4,Carbon fiber products: UAV carbon fiber refitted component for automobile;radon ;carbon fiber square tube ;carbon fiber panel; carbon fiber automobile bonnet

Q1: How is the quality of your products made via hand lay up process?

A: More than 90 % workers have been working in our factory for over 10 years, which ensures the continued stability of our production, quality management, research and development,especially for hand lay up products. This will save cost for you and provide you with competitive products. We are pround of our quality of the solidified gel-coat surface, which is highly spoken by our customers.

Q2: Which market have you exported your products to?

A: Europe, North America, Australia, New Zealand, Middle East. The products are applied as auto parts, motorcycle parts, construction parts, public facilities(like telephone booth), marine parts, industrial machine parts, household parts, etc. This makes us know well about the request from these market and product.

Q3:What process are you specialized in?

A:We are good at FRP( Fibre Reinforced Polymer/Plastic ), hand lay up and RTM process

Q4: Which process are suitable for my products?

A: Please just send your product details to us and our engineer will evaluate for you, based on your annual quantity, product structure, your detailed request, etc.

Q5: How far is your factory from the sea port?

A:It's about 100km from port to our factory. We are warmly welcome you to visit us for knowing our capability and our production lines.